20th May 2015 A breakthrough in large-scale graphene fabrication One of the barriers to using graphene at a commercial scale could be overcome using a new method demonstrated by researchers at the Department of Energy's Oak Ridge National Laboratory (ORNL).

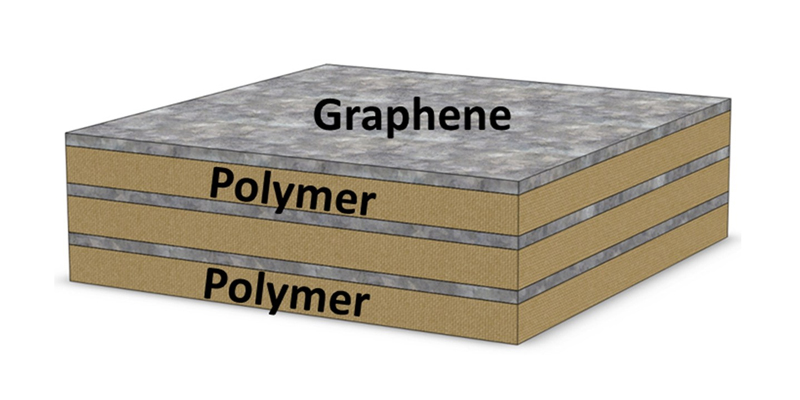

Graphene – a material stronger and stiffer than carbon fibre – has enormous commercial potential, but has been impractical to employ on a large scale, with researchers limited to using only small flakes of it. Now, using chemical vapour deposition, a team at the ORNL has fabricated polymer composites that contain 2-inch-by-2-inch sheets of the one-atom thick, hexagonally arranged carbon atoms. The findings, reported in the journal Applied Materials & Interfaces, could help usher in a new era of flexible electronics and change the way this reinforcing material is viewed and ultimately used. "Before our work, superb mechanical properties of graphene were shown at a micro scale," said Ivan Vlassiouk, who led the research. "We have extended this to a larger scale, which considerably extends the potential applications and market for graphene." While most approaches for polymer nanocomposition construction employ tiny flakes of graphene or other carbon nanomaterials that are difficult to disperse in the polymer, the team used larger sheets of graphene. This eliminates the flake dispersion and agglomeration problems, allowing the material to better conduct electricity with less actual graphene in the polymer.

"In our case, we were able to use chemical vapour deposition to make a nanocomposite laminate that is electrically conductive – with graphene loading that is fifty times less compared to current state-of-the-art samples," said Vlassiouk. This is a key to making the material competitive on the market. If Vlassiouk and his team can reduce the cost and demonstrate scalability, researchers envision graphene being used in aerospace (structural monitoring, flame-retardants, anti-icing, conductive), the automotive sector (catalysts, wear-resistant coatings), structural applications (self-cleaning coatings, temperature control materials), electronics (displays, printed electronics, thermal management), energy (photovoltaics, filtration, energy storage) and manufacturing (catalysts, barrier coatings, filtration).

Comments »

|