4th October 2019 3D-printed rocket company to begin commercial launches in 2021 Relativity Space aims to create the world's first entirely 3D-printed rockets – built within days, rather than years. Funding has now been secured for its first commercial operations in 2021.

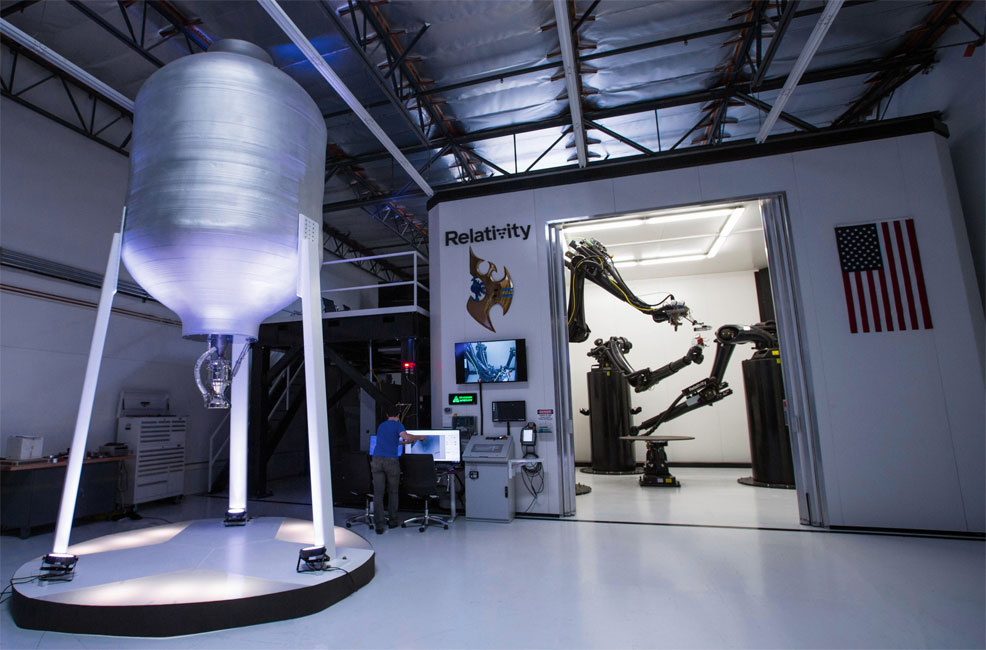

Founded in 2015, Relativity Space is developing both the world's first autonomous rocket factory and the first entirely 3D-printed rocket. The company's vision is to accelerate progress in space travel by enabling a much faster and simpler construction process for launch vehicles. Unlike the 60,000+ components of traditional rockets, Relativity is aiming for just 700 or so: nearly two orders of magnitude less. As a result, the timeline from raw material to flight could be slashed from two years to just 60 days – greatly improving lead times, flexibility and costs. In order to 3D-print large components, Relativity has created a system named "Stargate" which it claims is the world's largest 3D printer of metals. It is based on selective laser sintering, which uses laser beams to bond powdered metal, layer by layer, into precise and complex structures with minimal parts. The company aims to 3D-print and deploy their first complete launcher – known as Terran 1 – by the end of 2020, with commercial launches to follow. This week, Relativity Space announced that it had closed a $140 million Series C funding round, led by Bond and Tribe Capital. This means that full funding has now been achieved for commercial services beginning in 2021. "Relativity was founded with the long-term vision of 3D printing the first rocket made on Mars and expanding the possibilities for human experience in our lifetime," said Tim Ellis, co-founder and CEO of Relativity Space. "With the close of our Series C funding, we are now one step closer to that vision by being fully funded to launch Terran 1 to orbit as the world’s first entirely 3D-printed rocket. Bond and Tribe are unrivalled partners in leading this funding round, and we are excited to build this important future together with our entire team." Stargate is the first and only aerospace factory to integrate machine learning, software, and robotics with metal 3D printing technology, enabling Relativity to work extremely rapidly. With a payload capacity up to 1,250 kg (2,756 lb), orbital heights of up to 1,200 km (746 miles), and a recently upgraded fairing with two times larger volume than before, Terran 1 is claimed to be the most competitive rocket in its class, with unique flexibility for satellite customers. Both the Stargate factory and Terran 1 are completely designed, built and operated in the United States.

Since closing a Series B fundraising round in March 2018, Relativity has achieved a number of key milestones: expanding its production capacity four-fold and developing larger, next-generation 3D printers; improving scalability and adaptability for evolving customer needs; fully printing the first and second stage prototype structures; successful pressure and turbopump tests; completion of more than 200 engine hotfire tests at NASA Stennis Space Center; completion of the avionics architecture and hardware testing; and completion of the Terran 1 vehicle system design and coupled loads analysis. "We are excited to complete the development of Terran 1, providing an entirely new value chain for our customers. As we build Terran 1, we will continue to expand the Stargate factory, achieving another milestone towards our long-term vision," said Jordan Noone, co-founder and CTO of Relativity Space. Relativity already has a growing list of clients – including leading global satellite operators, commercial companies, and government payloads. The company previously announced contracts with Telesat, to support its LEO constellation; mu Space, the innovative Thai satellite and space technology company, to launch their first LEO satellite; Spaceflight Industries, a satellite rideshare and mission management provider, to launch Spaceflight’s dedicated smallsat rideshares; and most recently, Momentus, a new provider of in-space shuttle services, to launch small and medium satellites to GEO. Each launch is priced at around $10 million. Relativity is the first venture-backed company to have secured a launch site Right of Entry at Cape Canaveral Launch Complex-16 from the U.S. Air Force, secured a 20-year exclusive-use Commercial Space Launch Act (CSLA) agreement for five NASA test sites and a 20-year lease for a 220,000 square feet factory at NASA Stennis Space Center. Relativity expects to secure a polar and Sun Synchronous Orbit (SSO)-capable launch site (for higher orbits) by the end of 2019. "We're thrilled to invest behind Relativity's world class team, and join a broader group of investors, customers, and government partners that share our enthusiasm for the company's bold vision to reimagine rocket development," said Noah Knauf, Cofounder and General Partner at Bond. "We believe the Stargate factory is a template for the future of aerospace manufacturing and provides Relativity's commercial customers, and eventually humanity, a faster, more reliable, and lower cost way to shuttle important resources from Earth to outer space." "Accelerating speed in the design, manufacture and delivery of rockets will become the Moore's Law of space travel and exploration," said Arjun Sethi, Cofounder and General Partner at Tribe Capital. "By optimising manufacturing for speed, Relativity will increase the frequency of launches in service of growing commercial and consumer needs in space. Just as doubling microprocessor speeds enabled the personal computing revolution, Relativity will push forward an entire ecosystem of hardware and software systems to take humanity beyond Earth's orbit." While still a fledgling company, Relativity is growing fast and has solid financial backing. It counts former engineers from SpaceX and Blue Origin among its staff and may become a rival to those companies at some point in the future. Its innovative 3D printing approach could well be a game-changer – offering advantages that the larger and more established companies are unable to match at present.

Comments »

If you enjoyed this article, please consider sharing it:

|